How To Set Up Fractional Distillation Apparatus

5.3D: Footstep-by-Stride Procedures for Partial Distillation

- Page ID

- 95721

Partial Distillation Procedure

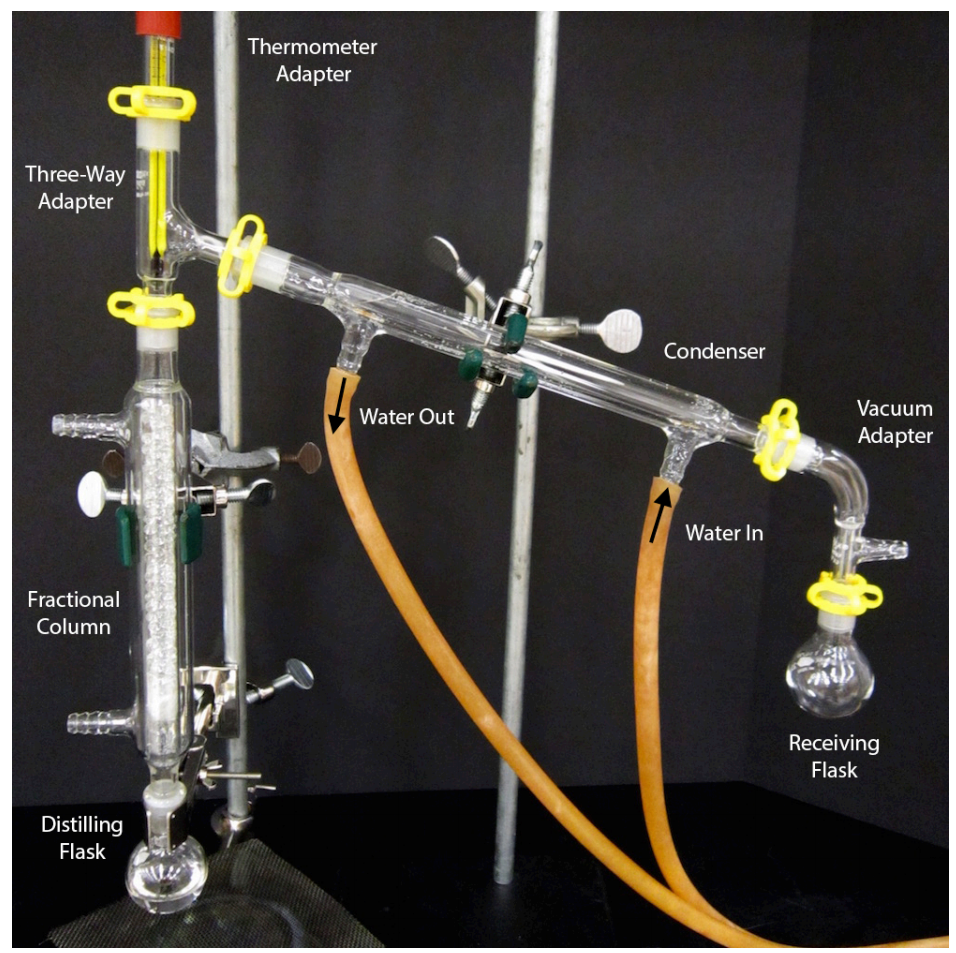

An assembled fractional distillation apparatus is shown in Figure v.43, using drinking glass beads in the fractionating column. Other columns may be substituted. Information technology is causeless that readers accept previously performed a elementary distillation, and then in this department are described differences betwixt unproblematic and fractional distillation.

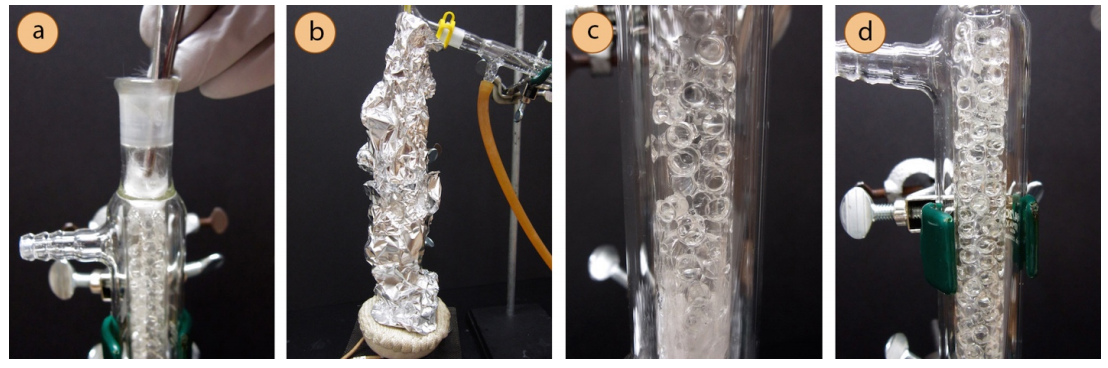

- If a beaded fractionating column is used, sometimes a wad of glass wool is inserted into the top so that the beads practise not spill out. Before using the cavalcade, remove this wad as it may interfere with the passage of vapors (Figure v.44a). If using a Vigreux column, cheque for broken glass indentations (which would case a leak in the column).

- The distilling pot will need to be heated much more vigorously than with a simple distillation, as there is a greater altitude for the vapors to travel before reaching the condenser. The vapors will tend to reflux in the cavalcade (condense and drip back into the distilling pot) unless stronger heating is applied.

A rule of pollex is that the distilling pot needs to be \(30^\text{o} \text{C}\) hotter than the top of the column in gild for material to ascend the column. If information technology is difficult to reach more than than a reflux, the cavalcade can be insulated by wrapping information technology with glass wool and then aluminum foil (Effigy 5.44b). This allows the column to maintain heat and the sample to remain in the gas phase longer. A small gap can be left in the foil or glass wool if desired to "peek in" on the action in the cavalcade.

- Ideally both liquid and gas should be seen in the fractionating column, as the sample needs to undergo many vaporization-condensation events (Figures 5.44 c+d). Droplets of liquid should exist seen on the surfaces of the packing fabric, but in that location should never by a large puddle of liquid. A "river" of liquid traveling up the cavalcade is called flooding (Figure v.45). If a cavalcade floods, remove the heat until the liquid drains back into the distilling flask, and then resume heating at a gentler rate.

- Cleaning of a fractionating column:

- Vigreux column: rinse with acetone. Don't use a scrub castor or the drinking glass indentations may break.

- Steel wool column. rinse with big amounts of acetone. Don't rinse with water every bit wet steel volition rust over time.

- Glass bead cavalcade: rinse with acetone, so replace the glass wool wad to prevent the chaplet from pouring out when horizontal. Alternatively, pour out the glass beads to exist cleaned separately. Be delicate when using a scrub brush on the fractionating column as there are fragile indentations nigh the bottom articulation which can intermission.

Fractional Distillation Summary

| Most comments for a simple distillation apply to fractional every bit well. The distilling pot will demand to be heated more than vigorously than with a simple distillation, as there is a greater distance for the vapors to travel earlier reaching the condenser. | Commonly the column will need to be insulated to maintain heat: wrap the column (and iii-style adapter if desired) in glass wool followed by an outer layer of aluminum foil. | Droplets of liquid should be seen in the fractional column, but in that location should never be a large pool of liquid (flooding). If the column floods, let the liquid to drain back into the distilling flask and oestrus at a gentler charge per unit. |

Source: https://chem.libretexts.org/Bookshelves/Organic_Chemistry/Organic_Chemistry_Lab_Techniques_(Nichols)/05%3A_Distillation/5.03%3A_Fractional_Distillation/5.3D%3A_Step-by-Step_Procedures_for_Fractional_Distillation

0 Response to "How To Set Up Fractional Distillation Apparatus"

Post a Comment